Oven Controlled Crystal Oscillators (OCXOs) are critical components in RF and microwave applications, providing frequency control and timing reference. However, OCXOs are subject to aging, which can lead to shifts in frequency performance over time. While there are frequency control and timing components, like Micro-Electro-Mechanical Systems (MEMs), that are not subject to aging, OCXOs are the ideal choice for applications requiring frequency precision and ultra-low phase noise. In this blog, we give an overview of OCXO aging, shelf life, and several mitigation strategies. Let’s dive in!

OCXO aging refers to the gradual change in performance characteristics over time. This is a result of various factors, including component materials, manufacturing processes, and environmental conditions. While modern OCXOs are designed to be highly stable and reliable, they are not immune to the effects of aging.

Parts per billion per day (PPB per day) is the unit typically used to measure the rate of change in an OCXOs frequency over a 24-hour period. In precision frequency control and timing applications, this metric is very important. For instance, if an OCXO has an aging rate of 1 PPB per day, it implies that its frequency will, on average, change by one part per billion each day. Expressing OCXO aging in PPB per day provides a standardized way to communicate the expected rate of change. This metric helps engineers and designers assess the long-term stability of OCXOs. It also aids in system design and calibration routines, allowing for the necessary adjustments to maintain accuracy over time.

One contributor to aging is the crystal resonator, a key component. OCXOs utilize a quartz crystal that vibrates at a specific frequency when an electrical voltage is applied. Over time, this crystal can undergo changes in its physical structure, leading to shifts in frequency.

The inherent aging characteristics of quartz crystal resonators, and other frequency stability factors such as temperature variations, voltage fluctuations, and environmental conditions, are considered during the OCXO design phase and measures to mitigate the impacts are implemented.

During storage, OCXOs may be exposed to varying environmental conditions, and even without being actively used, they can undergo changes over time. Manufacturers specify a shelf life for their OCXOs to ensure that customers receive components that meet the required performance standards.

It is important to note that the shelf life of an OCXO is influenced by factors such storage conditions and the materials used in its construction. Manufacturers conduct extensive testing to determine the optimal storage conditions and the maximum duration that OCXOs can be stored prior to sale.

Mitigating the Effects of OCXO Aging

Even though OCXO aging is an inevitable process, designers and engineers can minimize its impact on RF and microwave systems. Some common approaches include:

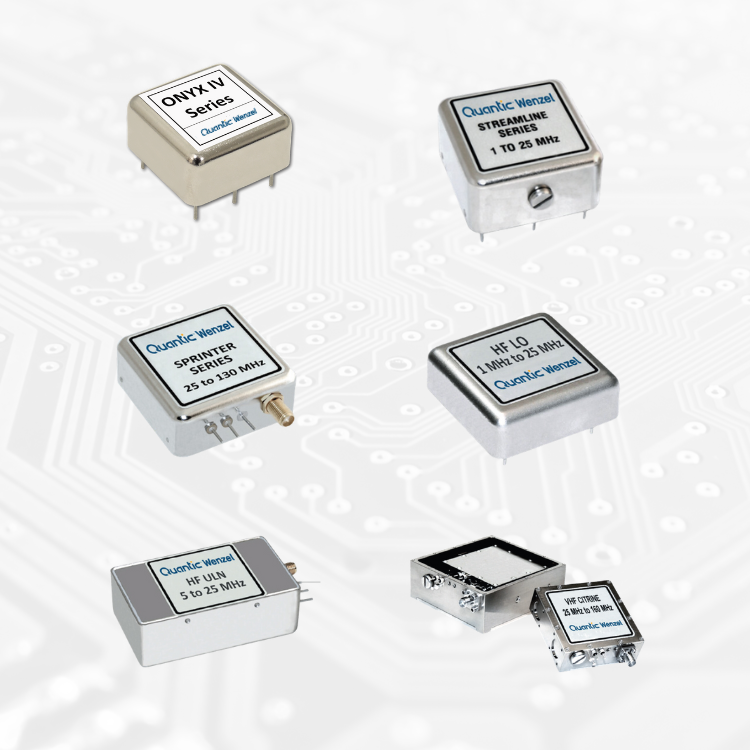

In summary, understanding OCXO aging and shelf life is important for maintaining the desired performance in radio frequency and microwave systems. While OCXO aging is unavoidable, design choices and careful handling during storage can significantly mitigate its impact. Quantic Wenzel’s OCXOs and quartz crystal resonators are built with high-quality materials, innovative engineering techniques, and rigorous testing that results in very low long-term aging, frequency precision, and ultra-low phase noise performance. Whether your RF and microwave application is aerospace, defense, or commercial, Quantic Wenzel is your trusted frequency control and timing partner.

Connect with us, we’re here to help!